At a glance, it may seem that science and technology have already delivered their peak achievement with generative AI. But a growing number of companies are offering a compelling answer to the question “what comes next?” It is the fusion of cognitive capabilities with physical embodiment—the ability to perceive the world, move through it, learn autonomously, and execute practical tasks. Humanoid robots, long confined to the domain of science fiction, are now progressing quickly thanks to breakthroughs in engineering and AI.

Market analysts are equally confident about this trajectory. Goldman Sachs projects that the global humanoid robotics sector could reach $38 billion by 2035. Costs of critical components such as sensors and actuators have dropped by roughly 40%, significantly improving the economics of building advanced platforms. At the same time, their capabilities are rising fast, allowing them to perform hazardous industrial operations and increasingly support everyday household activities. As a result, major tech corporations and ambitious startups are pushing substantial investment into humanoid systems, accelerating their shift from research labs into real commercial pilots.

The industry is shaping up to be the next big frontier, and it is no longer difficult to imagine a million-strong robotic workforce operating across business environments and home services alike. Even with high initial price points, interest continues to grow, and—just like any emerging market—competitive pressure will drive costs down while advancing performance.

For software companies, this shift represents a massive new opportunity. At Software Planet Group, we are closely tracking these developments and have begun experimenting with the first publicly available humanoid robot SDKs. In this article, we explore the most prominent humanoid robots on the market and examine the state of their development as the industry approaches the end of 2025.

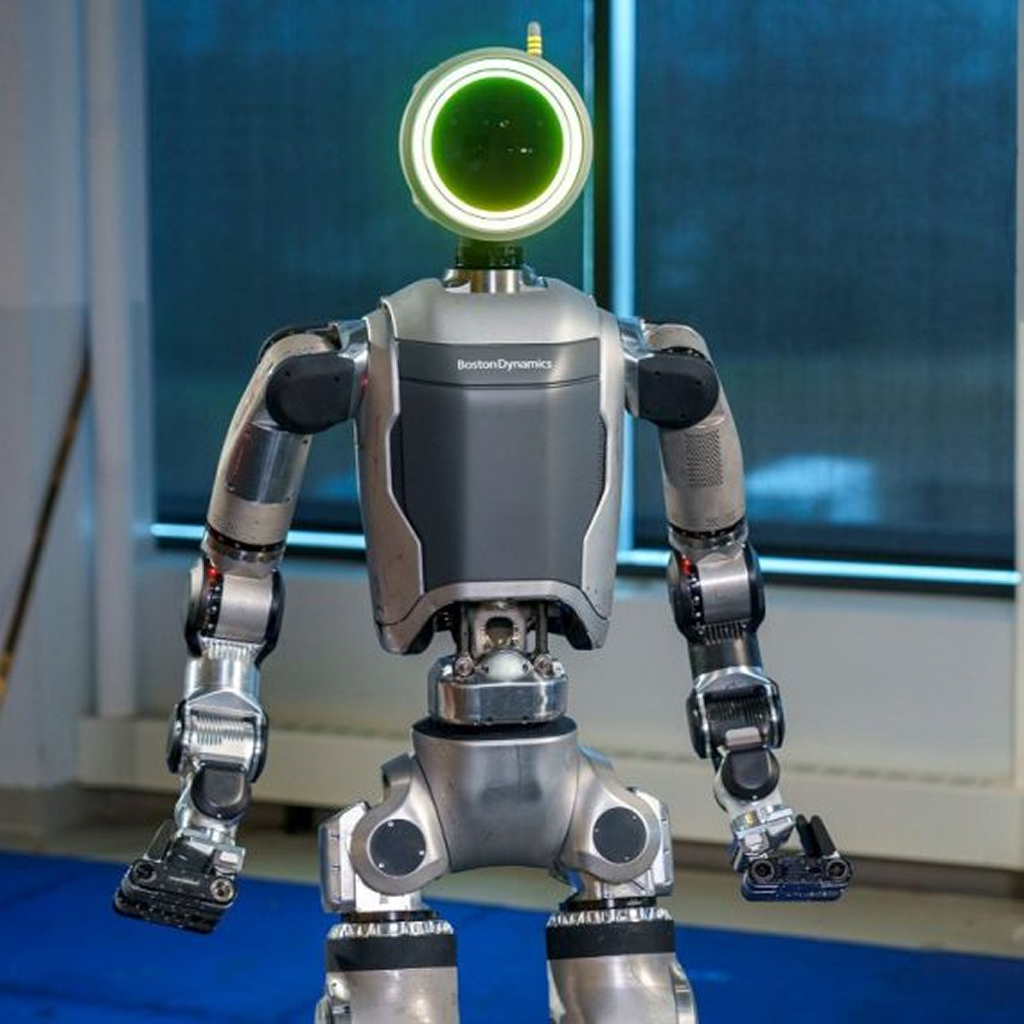

Boston Dynamics – Atlas

Boston Dynamics’ Atlas remains one of the most technically sophisticated humanoid robots in existence, known for its dynamic mobility, balance and whole-body coordination. Earlier generations of Atlas stood around 1.5 m tall and weighed roughly 85 kg, though the company no longer discloses precise specifications for the latest fully electric version. What is clear is that Atlas has evolved from a hydraulically driven research platform into an electrically actuated robot designed with real industrial applications in mind.

Advantages:

Atlas’s whole-body control algorithms allow it to move with exceptional agility, navigate complex terrain and carry out coordinated manipulation tasks. Recent demonstrations, including collaborations with Toyota Research Institute, showed Atlas executing multi-step manipulations guided by a Large Behavior Model capable of blending locomotion, balance and task execution. This makes Atlas a powerful platform for exploring hazardous industrial operations, handling materials, and performing tasks that require a combination of mobility and manipulation.

Disadvantages:

Atlas remains an advanced, high-cost R&D system rather than a commercially available product. The fully electric version introduced in 2024 marked the first serious attempt to transition the platform toward real factory-floor use, but by late 2025 it is still limited to pilot programs, including those with Hyundai Motor Company. The robot’s complexity and power demands remain significant, and although manipulation capabilities have improved, the platform is still evolving toward more refined and generalized dexterous hands.

Backed by Hyundai Motor Group, Boston Dynamics continues to position Atlas as a stepping stone toward practical deployment of general-purpose humanoid robots after more than a decade of pioneering research in the field.

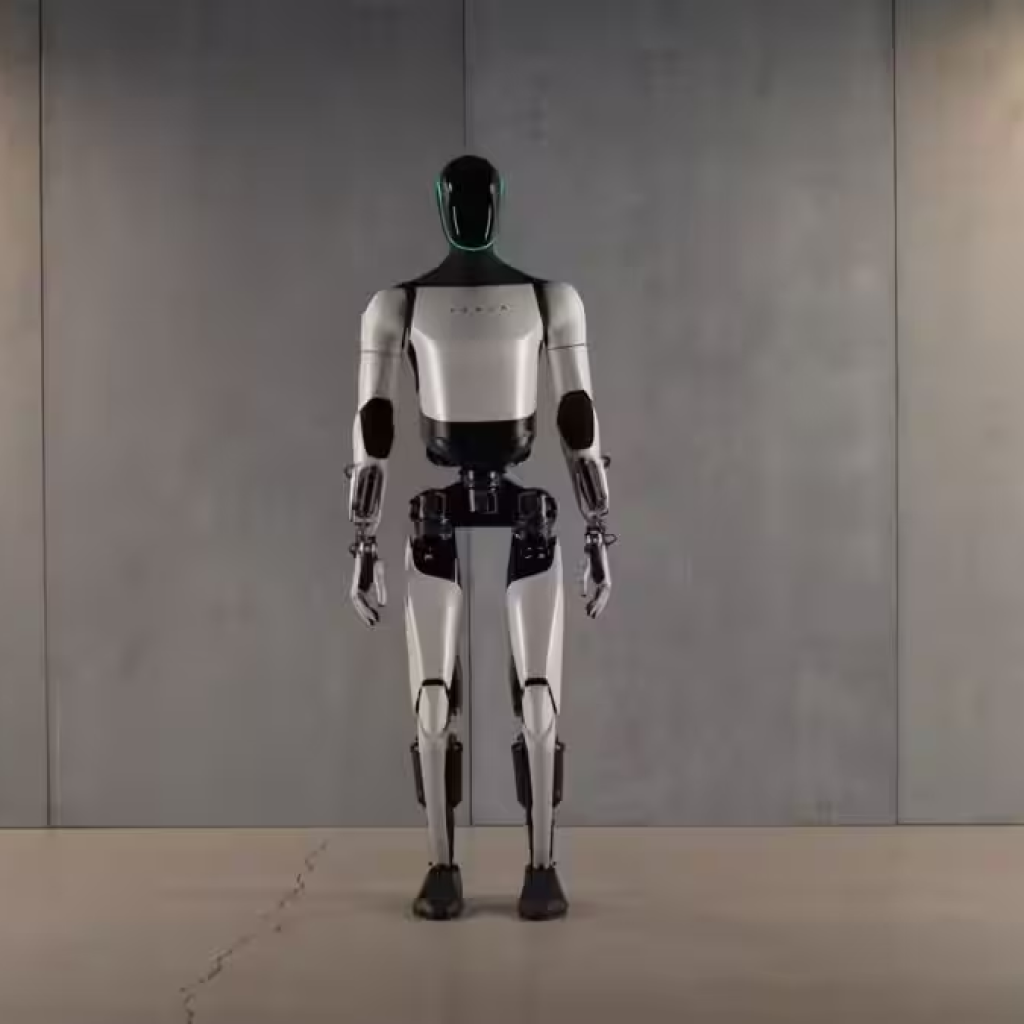

Tesla – Optimus

Tesla’s Optimus (also known as the “Tesla Bot”) is a general-purpose bipedal humanoid introduced by Elon Musk in 2021. The robot is intended to perform “unsafe, repetitive or boring” tasks in factories and homes by leveraging Tesla’s experience in batteries, motors and AI. The latest publicised version, labelled Optimus Gen 2 (and in some materials “Gen 2.5”), is reported to have a nominal height around 173 cm and weight near 57 kg — though Tesla has not fully verified these numbers in rigorous independent testing.

Tesla has demonstrated Optimus walking, carrying light objects and manipulating items (for example handling eggs in controlled conditions) — though many such demos still appear tethered to teleoperation or highly scripted environments.

Advantages:

Optimus’s design emphasises cost-effectiveness and mass-manufacturability: Musk has publicly stated ambitions to offer units priced under US$30,000 for consumers (though timing and final specification remain speculative). Further, Tesla intends to reuse its automotive-grade vision systems and AI software stack (originally developed for its self-driving vehicles) which gives the project a strong foundation in object recognition and navigation.

Disadvantages:

As of 2025, Optimus remains under development and is not yet commercially available on a meaningful scale. Reports indicate Tesla targetted production of thousands of units during 2025, but have encountered delays, production bottlenecks and component-supply issues (for example stemming from rare-earth magnet export restrictions).

The robot’s movements, while improving, are still relatively cautious in publicly available footage; significant challenges remain in hardware–software integration, battery life, and full autonomy. The timeline for mass deployment remains uncertain and Tesla faces intense competition from other robotics players.

In sum, while Tesla’s scale, ambition and resources position Optimus as a strong contender in the humanoid robot space, the practical transition from prototype to widely deployed service robot remains a major hurdle.

Agility Robotics – Digit

Agility Robotics, based in Oregon, focuses on legged robotic systems, and its flagship humanoid platform is Digit. Originally introduced in 2019–2020 as a successor to the earlier Cassie robot, Digit is a human-sized biped equipped with simple arms, lidar and camera sensors for perception. It can walk, climb stairs, carry moderate loads and operate both indoors and outdoors under typical warehouse conditions. Early prototypes were tested for warehouse runs and last-mile delivery experiments.

Advantages:

Digit has consistently demonstrated reliable locomotion in complex environments, which positions it strongly for logistics and material-handling roles. Since 2023, Amazon and several logistics operators have conducted pilot deployments, validating Digit’s performance in structured warehouse workflows. By 2025, Agility Robotics announced a new generation of Digit featuring improved battery endurance of around 4 hours of active operation, autonomous charging via docking stations, and refined end-effectors for more stable object handling. The company has secured substantial investment—including over $150 million in 2023 and an additional $400 million raised in 2025—and is completing a factory in Oregon with a stated production capacity of up to 10,000 units per year. This makes Digit one of the first humanoids realistically positioned for scaled industrial deployment.

Disadvantages:

Digit’s architecture remains optimized for lower-body mobility and box-handling tasks, which means it still lacks fine-manipulation capabilities comparable to more dexterous humanoids. Its autonomy performs well in structured logistics environments but is not yet suited for interactive service or household roles. Despite improvements, battery life and walking speed remain constraints for full-shift, human-equivalent productivity. Nevertheless, Agility’s tight focus on bipedal logistics gives Digit a clear, commercially viable niche that is likely to see early real-world adoption ahead of more general-purpose humanoids.

Figure AI – Figure 03

Figure AI, founded in 2022 in California, has rapidly become one of the most ambitious players in general-purpose humanoid robotics. The company developed its first prototype, Figure 01, within its first year, followed by Figure 02 in 2024, which introduced significantly improved mobility and five-fingered dexterous hands. In October 2025, Figure AI unveiled Figure 03, its third-generation humanoid designed not only for industrial environments but also for scalable production and eventual home use. Figure 03 continues the company’s focus on human-scale form (around 1.7 m tall) while improving joint performance, manipulation precision and overall efficiency.

Advantages:

Despite being a young company, Figure AI has secured some of the strongest backing in the sector. It raised $70 million in 2023 and an additional $524 million in early 2024 from major partners including Microsoft, NVIDIA and the OpenAI startup fund, pushing its valuation to roughly $2.6 billion. By the end of 2025, the company had strengthened multi-year collaborations with BMW to pilot its robots in automotive production, and Figure 03 was positioned as the first model engineered with scalable manufacturing in mind. Figure AI also publicly commits to non-military applications and works closely with AI labs to integrate large-model-based perception, planning and control, aiming to deliver versatile and ethically aligned humanoid systems.

Disadvantages:

Even with the introduction of Figure 03, all of Figure’s robots remain in pilot or pre-commercial phases. Long-term durability, safety and autonomy in real factory conditions have yet to be proven, and the company still lacks a track record of deploying robots at operational scale. The challenge of delivering a truly general-purpose humanoid remains formidable, and competition from more established robotics firms is intense. Nevertheless, with substantial funding, rapid engineering progress and strong AI partnerships, Figure AI is regarded as one of the leading contenders shaping the next generation of humanoid robots.

Sanctuary AI – Phoenix

Canadian firm Sanctuary AI is pursuing human-like intelligence in general-purpose humanoid robots. Its latest model Phoenix (the company’s seventh-generation humanoid) stands about 1.7 m tall and 70 kg, with two arms and fully articulated five-fingered hands. Sanctuary’s approach emphasises cognitive AI software (called “Carbon”) to give the robot human-like understanding and decision-making in complex tasks. In 2024, Phoenix robots were successfully tested performing real work shifts in retail stores, warehouses, and light manufacturing environments. Initially these trials involved human teleoperators guiding the robots, but Sanctuary is progressively increasing the autonomy of Phoenix as its AI improves.

Advantages:

Sanctuary AI’s robots excel in human-robot interaction and adaptability. The company has integrated advanced tactile sensing, vision and hydraulics into Phoenix, allowing it to handle delicate tasks and operate for longer periods than earlier versions. Sanctuary’s partnership with Microsoft provides access to extensive cloud computing resources to train its AI (“large behavior models”), accelerating learning from real-world data. The company has backing from notable investors (over $140 million raised) and a manufacturing alliance with Magna International to gear up for production of Phoenix units.

Disadvantages:

Achieving “human-equivalent” general intelligence is extraordinarily complex – Sanctuary’s robots still rely partly on remote operators and scripted behaviors for many tasks. The hardware, with its many degrees of freedom, is expensive and intricate, which could hinder mass deployment until costs come down. Sanctuary’s focus on broad capability means it may not yet be as optimized for any single task compared to more specialised robots. Even so, its progress with Phoenix performing varied jobs is a promising step toward versatile humanoid assistants.

Apptronik – Apollo

Apptronik, headquartered in Austin, Texas, introduced the Apollo humanoid robot as a versatile commercial platform intended for real-world industrial and logistics applications. The robot stands about 1.73 m (5′8″) tall, weighs around 72.6 kg (160 lbs), and carries a payload of up to ~25 kg (55 lbs) in its current iteration. It features modular architecture, hot-swappable battery packs with approx. four-hour runtime, and actuators derived from the company’s heritage in legged and humanoid robotics.

Advantages:

Apollo benefits from a development team experienced in NASA robotics programs and emphasizes manufacturability and deployment readiness. The robot is marketed for logistics and manufacturing roles—moving materials, palletising items, assisting in warehouses and factories. Apptronik secured a major funding round of $350 million in early 2025 to scale Apollo’s production and is testing the platform with partners such as Mercedes-Benz and Jabil.

Disadvantages:

Despite significant progress, Apollo remains in pilot and testing phases with real-world deployment still limited. The payload capacity is moderate compared to heavy-duty industrial robots, and battery runtime remains a constraint. The robot’s degree of freedom and manipulation capability—while strong for its class—are not yet at the level required for broad dexterous service-robot tasks. Intense competition from both specialised robotic arms and other humanoids means Apollo must further prove cost-effectiveness to achieve scale.

UBTECH Robotics – Walker

Chinese robotics firm UBTECH Robotics (Shenzhen) has significantly advanced its humanoid robot lineup. The current flagship is the Walker S2, officially launched in 2025, which marks a major step beyond earlier home-assistant ambitions. The Walker S2 is designed for industrial and logistics tasks, with full-size bipedal form, autonomous battery-swapping capability and deployment in real factory environments.

Advantages:

UBTECH has achieved tangible commercial milestones: the Walker S2 has entered mass production and delivery, with reported orders exceeding 800 million CNY (~US$112 million) by late 2025. Major industrial clients include automakers such as BYD, Geely Auto, and Foxconn. The Walker S2’s key innovations include a hot‐swappable dual-battery system that allows the robot to autonomously replace its power pack and resume operation within minutes—enabling near 24/7 deployment in manufacturing settings. UBTECH is targeting production capacity of 5,000 units per year by 2026 and up to 10,000 by 2027.

Disadvantages:

Despite the progress, Walker remains firmly focused on structured industrial use rather than home applications. Although Walker S2 is entering real deployments, questions remain about long-term reliability, versatility in non-industrial settings and cost-effectiveness compared to more narrowly specialised robotic systems. For consumer or general-service purposes the robot is not yet proven. Moreover, earlier marketed versions oriented for home assistance have been largely sidelined in favour of logistics and factory roles.

Unitree Robotics – H1

Unitree Robotics, headquartered in Hangzhou, China, initially made its name with affordable quadruped robots. In 2023 the company introduced its full-size humanoid robot H1, which has since become one of the most cited humanoid platforms in China. According to company materials, the H1 stands approximately 1.80 m (≈5′11″) tall and weighs around 47 kg in current configurations. It includes high-torque actuators, LiDAR and depth-camera perception systems, and a design geared toward dynamic bipedal locomotion.

Advantages:

The H1’s standout feature is its speed: Unitree claims the H1 reached running speeds of up to 3.3 m/s under controlled conditions, which positions it among the fastest humanoid robots publicly demonstrated. Unitree’s cost-oriented manufacturing strategy is also notable: given the company’s experience in cost-efficient quadrupeds, the H1 is marketed at a significantly lower price point than many Western counterparts — initial listings suggest a pricing around US $90,000 in China. At the same time, Unitree benefits from established supply-chain infrastructure and vertical integration, which gives it potential scale advantages for industrial pilot deployment.

Disadvantages:

Despite its impressive locomotion, H1 remains largely a research/development platform and is yet to see widespread deployment in diverse operational roles such as tool use, handling, or long-duration autonomous service. Many claims (such as “runs at 5 m/s”) remain potential rather than proven in commercial settings. Safety incidents have also surfaced: a public video in 2025 showed a Unitree H1 model exhibiting uncontrolled behaviour in a factory setting. ([turn0search15]) Further, while the price is lower than many high-end humanoids, the H1 still remains expensive for broad consumer or service-robot markets. Its utility outside structured environments is still unproven.

Fourier Intelligence – GR-2

Shanghai-based Fourier (formerly Fourier Intelligence) has introduced the GR-2 humanoid robot as the successor to its GR-1 platform. The GR-2 stands about 1.75 m tall, weighs approximately 63 kg, and features 53 degrees of freedom including 12-DoF dexterous hands with embedded tactile sensors.

This next-generation model is designed for practical deployment in industrial, research and service contexts, emphasising modular architecture, improved actuator performance (up to ~380 Nm torque), and detachable batteries supporting up to ~2 hours of runtime.

Advantages:

GR-2 benefits from Fourier’s heritage in robotics and rehabilitation systems: the use of their “Fourier Smart Actuator” modules, open ROS-based architecture and developer-friendly design make the platform accessible for integration and experimentation. With the upgraded hands and tactile sensing, GR-2 is capable of more refined manipulation tasks than GR-1, making it more viable for real-world applications in manufacturing, labs and service environments.

Disadvantages:

Despite these advances, GR-2 remains in early production and pilot-stage deployments as of late 2025. Its autonomy, durability in unsupervised operations, and cost-effectiveness in broad service roles are still unproven. The payload capacity and runtime remain moderate compared to human workers or specialty robots. Further, while the hardware has been upgraded, transition from prototype to reliable mass-commercial robot still poses significant challenges.

Neura Robotics – MIRA and 4NE-1

Germany’s NEURA Robotics, headquartered in Metzingen, is pushing into the humanoid robotics space with its robot 4NE-1 (“For Anyone”). The company describes 4NE-1 as its third-generation full-size bipedal humanoid platform, unveiled in 2025 and intended to operate in both industrial workflows and everyday human environments. Through the 4NE-1, NEURA emphasises “cognitive robotics” — robots equipped with advanced multi-modal perception (3D vision, LiDAR, artificial touch-skin), embedded AI and an ecosystem of skills called Neuraverse that enables robots to learn from experience and share capabilities across devices.

Advantages:

4NE-1 is built around a concept of human-robot collaboration and adaptability. NEURA claims the robot will work safely alongside humans, without protective cages, and is developing tactile sensor ‘skin’ modules, voice-gesture interaction, and cloud-based skill upgrades via Neuraverse. The company has secured large financing (e.g., around €120 million in early 2025) to scale up production. NEURA is also entering partnerships with Tier-1 suppliers and industrial firms, aiming to ramp up manufacturing in Germany and target mass-market deployments over the coming years.

Disadvantages:

As of late 2025, 4NE-1 remains in early production and pilot phases. There is limited independent verification of its ability to perform unsupervised tasks in dynamic real-world settings such as elder-care or home assistance. Many of the claims remain aspirational rather than proven at scale. Operating costs, durability, autonomy and safety compliance still present challenges. Moreover, while NEURA pursues both industrial and domestic markets, competing firms target more narrowly defined use-cases, which may offer better early-market traction.

Toyota Research Institute – T-HR3

Toyota’s T-HR3 is a humanoid robot developed by the company’s Partner Robot Division (via the Toyota Research Institute) and first unveiled in 2017. It is primarily a teleoperated android: an operator uses a wearable Master Maneuvering System and data-gloves, and T-HR3 mirrors the user’s motions in real time. The robot was initially showcased at roughly 1.5 m in height and 75 kg in weight with 32 degrees of freedom, though Toyota has not publicly issued major updates to the physical platform since.

Advantages:

T-HR3’s teleoperation architecture allows extremely precise and reliable motion replication: the human operator remains in the loop, which bypasses many of the autonomy challenges that plague fully independent robots. Toyota has demonstrated remote control of T-HR3 over 5G networks, allowing operation from a distance of up to 10 km (as reported in 2018).

The platform is described by Toyota as a technology foundation to “amplify, not replace” human workers, enabling skilled technicians to perform tasks in hazardous or remote environments via the robot.

Disadvantages:

As of 2025, T-HR3 has not been commercialised and remains a research prototype. Its teleoperation paradigm means each robot requires a dedicated human operator, limiting scalability and labour-savings potential. Autonomy beyond direct human control is minimal or not publicly documented, and Toyota has emphasised that the robot is meant as a development platform rather than a full production system.

Engineered Arts – Ameca

Engineered Arts, based in the UK, is best known for Ameca, widely regarded as the most lifelike humanoid robot in terms of facial expression and social presence. Ameca stands around 1.87 m tall and incorporates 61 actuated degrees of freedom across the face, neck, arms and torso, enabling highly natural gestures and nuanced expressions. Designed specifically for human interaction rather than physical labour, Ameca engages in conversation through speech-driven AI systems and is frequently showcased in museums, exhibitions and public events.

Advantages:

Ameca’s realism and responsiveness make it particularly suited for customer-facing environments, education, hospitality and entertainment. Its expressive face, fluid upper-body motion and multilingual conversational capabilities have been steadily improved through updates to both hardware and AI, including integration with large language models to support more natural dialogue. The robot has become a prominent demonstration platform at global tech events, illustrating the potential of socially intelligent humanoids.

Disadvantages:

Ameca is not designed for mobility or heavy manipulation. It cannot walk independently and is typically stationary or mounted on a wheeled base. Its hands are suitable for gesturing but not for practical manual tasks. The sophisticated hardware and limited production volumes result in high costs, restricting Ameca mainly to research institutions, corporate showcases and rental environments rather than broad deployment. While it excels as a social robot, it is not intended for industrial roles or physically demanding work.

The humanoid robotics sector in 2025 is evolving at remarkable speed, with major tech companies and ambitious startups simultaneously shaping its trajectory. Industrial humanoids are steadily expanding their capabilities, demonstrating stable locomotion, precise manipulation and reliable operation in environments that once seemed far beyond reach. Service-oriented and social robots are also gaining ground, moving into customer interaction, education and healthcare. What used to be research-lab demonstrations has matured into commercially relevant functionality. With continued investment from players such as Tesla, Figure AI and Sanctuary AI, the expectation is clear: humanoid robots will become a familiar presence in professional environments over the coming decade.

The industry, however, is still navigating substantial constraints. Battery capacity, hardware expense, limitations in dexterity and the inherent complexity of human-level decision-making keep most humanoids confined to pilots or highly specialised workflows. A truly general-purpose robot — one that matches the adaptability of a human — remains an unsolved challenge. Safety and long-term reliability are equally critical, as these machines must operate beside people for hours without faults. Even so, the direction of progress is unmistakable. From manufacturing plants and construction zones to retail spaces and eldercare facilities, humanoid robots are beginning to establish real-world value. Over the next few years, several of today’s prototypes are likely to transition into production systems, moving the field closer to its long-term goal: machines working alongside humans, enhancing productivity, reducing labour shortages and expanding what organisations can achieve.

For software development companies, this shift marks the beginning of a new era. Building applications for humanoid robots demands skills and mindsets that go far beyond traditional programming. Developers must engage with frameworks designed for embodied intelligence, real-time control, multimodal perception and continuous decision-making. Businesses will need to adapt their internal processes, invest in targeted training and prepare teams for an entirely new class of engineering challenges. Companies that act early — learning the tools, methodologies and constraints of humanoid robotics — will be the ones positioned to lead as this industry moves from experimentation to widespread adoption.